Choosing a lining system for a welded steel tank in the drinking water industry is a team effort among owners, engineers, contractors, and manufacturers. Following the correct AWWA standard is crucial in protecting assets when specifying a lining system.

Understanding the various NSF 600/61-approved interior barrier coating types can mean the difference between a system that is compliant and performs versus one that fails to meet the established guidelines or owners’ life cycle expectations.

NSF/ANSI/CAN 61 [NSF 61] sets the standards for drinking water system components, while NSF 600 focuses closely on the extractable solvent levels in barrier coatings. Updates to NSF ratings have increased misconceptions about which systems are truly compliant, making the specification process more complex.

In January 2023, allowable extractable solvent levels changed, and solvents like toluene, xylene, and ethylbenzene were functionally removed from specified lining systems. Allowed parts per billion were drastically reduced from the previous specified criteria. This reduction in extractables forced some coatings manufacturers to alter the formulations of solvent-based barrier epoxies for interior potable water service. A shift was made to higher-volume solids epoxies that incorporated exempt solvents that fell under the revised extractable levels.

| Solvent | Total allowable concentration (TAC) | Single product allowable concentration (SPAC) | |

|---|---|---|---|

| Xylene | Previous | 10,000 ppb | 1,000 ppb |

| Current | 90 ppb | 9 ppb | |

| Toluene | Previous | 1,000 ppb | 100 ppb |

| Current | 60 ppb | 6 ppb | |

| Ethylbenzene | Previous | 10,000 ppb | 1,000 ppb |

| Current | 90 ppb | 9 ppb | |

Understanding new AWWA D102-24 standards

Currently, six systems are listed in the AWWA D102-24 standards. These interior coating systems (ICS) dictate critical minimum performance criteria, including surface preparation, coatings type (epoxies, polyurethanes, zinc-rich primers), total number of coats, minimum film thickness, and associated standards they must comply with, for example, AWWA C210/C222 or SSPC Paint 20.

Final system selection is based on factors such as tank size, curing capabilities, applicator preference, and weather conditions to meet return to service requirements, life cycle expectations, budgets, or support applications in cold weather environments.

The six AWWA D102 Interior Coatings Systems are as follows:

- • ICS #1 – 2-coat epoxy - 8 mils DFT

- • ICS #2 – 3-coat epoxy - 12 mils DFT

- • ICS #3 – 1-coat ultra-high solids epoxy - 20 mils DFT (Optional zinc-rich or epoxy primer)

- • ICS #4 – 1-coat ultra-high solids elastomeric polyurethane - 25 mils DFT (Optional zinc-rich or epoxy primer)

- • ICS #5 – 3-coat zinc-rich primer/epoxy/epoxy - 10.5 mils DFT

- • ICS #6 – 2-coat zinc/epoxy - 12.5 mils DFT

The ICS designations are intended to simplify industry communication and decrease confusion over product application compliance. While terminology barriers have been reduced, many owners still face the challenge of selecting the optimal system given their specific project circumstances, service life requirements, and budget pressures. A more detailed explanation of each system is below.

AWWA ICS #1 is a thin-film interior lining system for potable water tanks, requiring a solvent-based epoxy liner suitable for immersion and contact in potable water environments. ICS #1 calls for minimum dry film thicknesses of between 3 and 5 mils. Thin-film epoxies like Carboguard 635 VOC, Hydroplate 1080, and Hydroplate 1086 are ideal choices for ICS#1. These solvent-based epoxies wet out the steel surface effectively, have long pot lives, and can be sprayed using conventional airless spray equipment.

AWWA ICS #2 is a three-coat solvent-based epoxy system with additional film build for improved barrier protection and longevity. The same products mentioned above remain the ideal choices for ICS #2, with the decision reliant on life cycle expectations, timeline restrictions, and ultimately project budget. While #2 offers greater durability as a 3-coat system, the added protection may not justify labor and material costs for every project, emphasizing the need for consultation between owners and contractors.

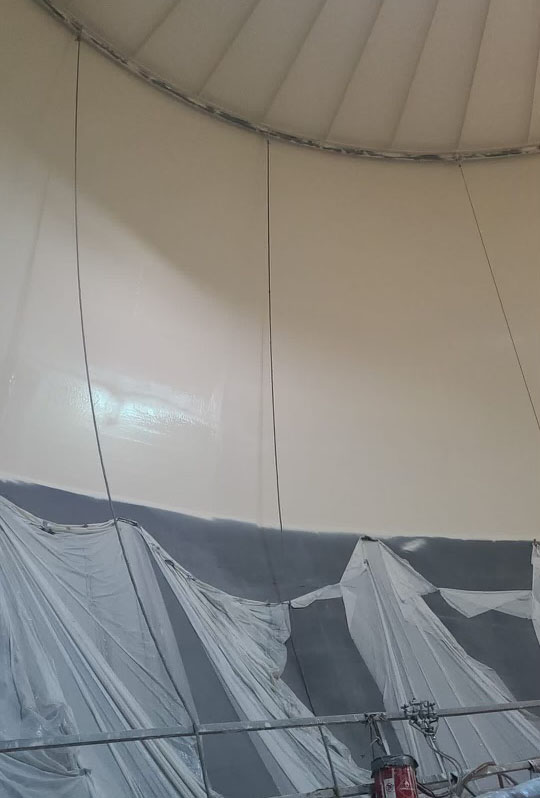

AWWA ICS #3 specifies a single-coat, high-film build lining system consisting of an ultra-high solids epoxy. The system achieves a minimum film build of 20 mils DFT and can be applied directly to abrasive blasted steel as a single coat or over an optional epoxy, organic, or inorganic zinc-rich primer. UHS epoxies in this specification provide high-performance qualities, like edge retention, no taste and odor issues, rapid cure times (often less than 24 hours), high abrasion resistance, and ultra-low VOC content.

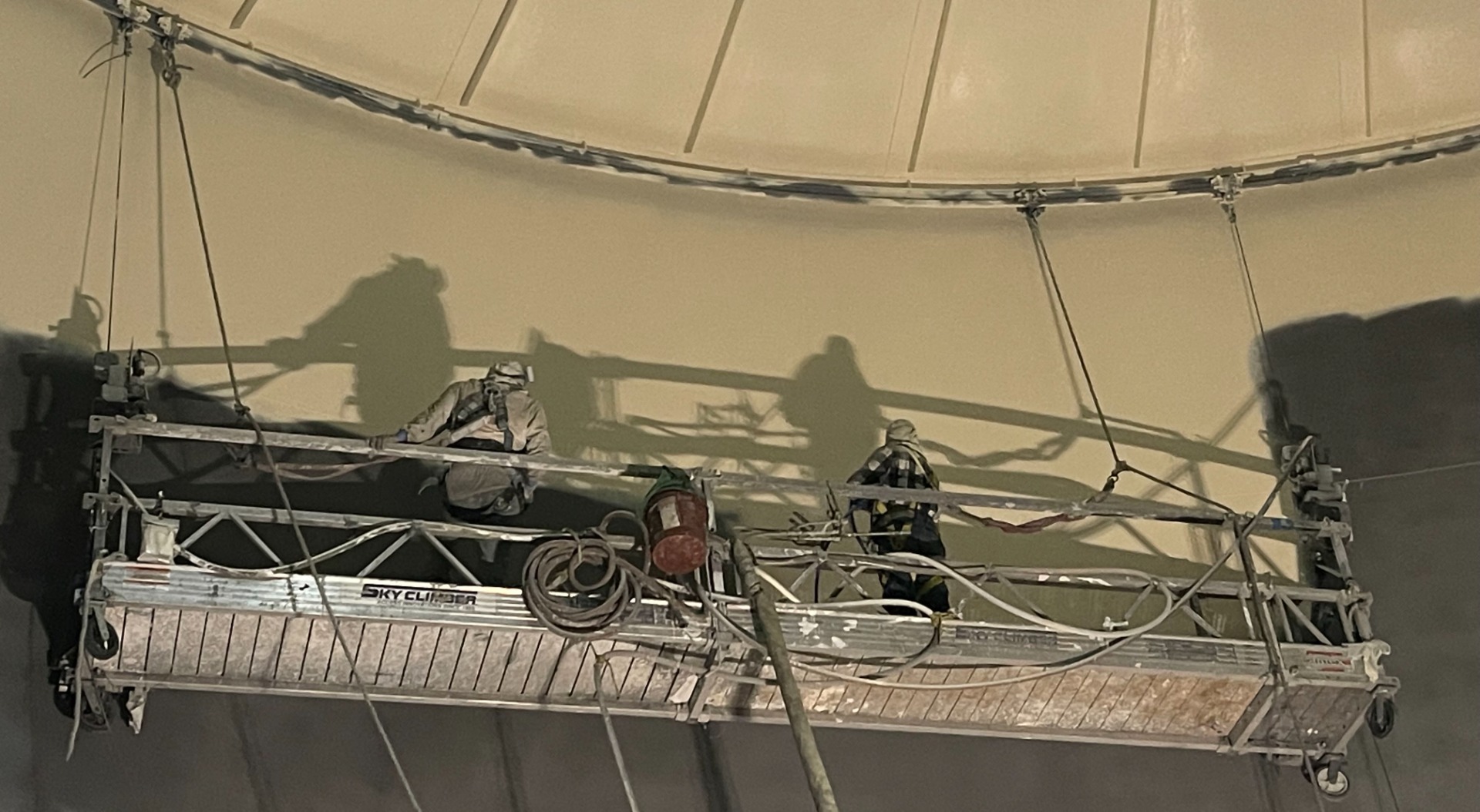

Ultra-high solids epoxies historically have featured very little usable pot life; therefore, application with heated, plural-component spray equipment was necessary. This is where both components are conditioned and proportioned separately and sent to a remote mixing manifold, where they are rapidly mixed together and sent through a short whip hose to the spray gun to be applied.

Recent advancements in coatings technology allow for a more functional 30-45 minute pot life at 77°F (25°C), allowing applicators to hand-mix the material similarly to traditional solvent-based epoxies and spray through conventional airless spray equipment. This significantly reduces the complexity and expense of applying UHS epoxy systems. Specifying products exhibiting high film build and enhanced cure times, like Hydroplate 1100 or Hydroplate 6500, allows applicators to take advantage of long pot lives, high film build, zero taste and odor issues, and fast cure to service times (24-36 hours).

AWWA ICS #4 specifies an optional zinc or epoxy primer with 25+ mils of an elastomeric polyurethane that incorporates high-build, flexible films with chemical- and abrasion-resistant qualities. These properties are ideal for tanks subject to abrasive ice flows, potential movement, or in situations where the tank may be of bolted or riveted construction with problematic leaks. All these challenges are perfectly suited for a product like Reactamine 760.

The appeal of systems #3 and #4 lies in their use of ultra-high solids products that return assets to service quickly and perform for the long term. Both systems can provide over 18 years of service life.

AWWA ICS #5 specifies a zinc/epoxy/epoxy system with organic or inorganic zinc sprayed at 2.5 mils DFT minimum, followed by two coats of solvent-based epoxy at 4 mils DFT minimum. ICS #5 suits projects with complex roof structures where film build is challenging to achieve in a single spray pass. This allows applicators the flexibility to ensure proper coverage and thickness without film defects such as runs, sags, drips, or solvent entrapment.

AWWA ICS #6 specifies either an inorganic or organic zinc-rich primer at 2.5 mils DFT minimum, followed by one coat of epoxy at a minimum of 10 mils DFT. This system takes advantage of higher-volume solids epoxies to reach its total film build in one coat while still delivering the cathodic protection of a zinc primer in demanding environments, saving on labor costs and application times.

ICS #5 and ICS #6 both specify a zinc primer, such as Hydroplate MCZ, to hold the blast and also provide additional corrosion resistance through galvanic protection. Pairing this with a high-solids epoxy barrier coat, such as Hydroplate 1080 or Hydroplate 1086, delivers a high-performance, long-lasting corrosion protection system. The former consists of a phenalkamine formulation that exhibits low-temperature cure capabilities, making it ideal for cold-weather applications. The main difference between AWWA ICS #5 and AWWA ICS #6 is the additional labor required to apply two coats of epoxy versus one heavy coat, as both provide similar life cycle expectations to the owner.

Use budget and life cycle requirements to optimize system specification

Choosing between the six systems depends on performance qualities such as budgetary constraints, application methods, and life cycle expectations from the owner.

Municipal owners and engineers use modeling tools and research papers similar to AMPP Paper #17616 Expected Service Life and Cost Considerations for Maintenance and New Construction Protective Coatings work (Helsel & Lanterman) to extrapolate estimated variations in system cost and overall life cycle performance. Research such as this shows real-world data to compare the life cycle of a thin-film epoxy system, such as ICS #1 (approximately 10 years in potable water immersion), against a thick-film system such as ICS #3 or ICS #4 (both exceeding 18-20 years of service life before the first required practical maintenance). When owners compare the overall cost of installing a lining system (mobilization, containment, surface preparation, and application) with the life expectancy of the lining system, they can get a truer gauge of the exact value of a lining technology.

ICS systems #1, #2, #5, and #6 all rely on solvent-borne epoxies that require a minimum of seven days to fully cure in 77°F (25°C) with constant air movement. ICS systems #3 and #4 offer significant advantages in cure-to-service times, taste and odor, and lower life cycle costs. Though they require a higher film build (and thus more material), their ultra-high solids formulations contain no solvent to evaporate or be vented from the vessel, functionally eliminating taste and odor issues and increasing cure to service times. This is especially advantageous in VOC-restricted jurisdictions. Plus, their single-coat specification lowers the overall applied cost per square foot.

Balancing protection, performance, and budgets

NSF ratings continue to evolve, and selecting a compliant system greatly depends on each project's unique requirements. Manufacturers who keep pace with evolving industry standards are crucial partners in ensuring that the chosen system will adequately protect the asset while adhering to time constraints typical in maintenance and repair applications.

With qualities such as fast-cure, single-coat applications, and self-priming capabilities, each of Carboline’s UL-certified NSF 61/600-compliant products offers the potable water industry reliable protection. These can be successfully integrated into the appropriate AWWA D102-24 system to provide long-term asset protection to municipal water storage owners.

Explore all NSF 61/600-compliant linings here.

When manufacturers provide clear, accurate information on AWWA-compliant systems, owners can make more informed decisions about system specification. Access to a broad product portfolio gives them the flexibility they need when selecting system products.

Together, these factors strengthen collaboration among stakeholders committed to finding the right balance between performance, cost, and schedule.