Stakeholders interested in corrosion prevention are broadly aware that zinc is an excellent material for protecting assets in harsh environments.

Many also know why it works—anodes, cathodes, and the galvanic series—so we won't summarize that here.

But in the world of liquid-applied protective coatings, the interactions among zinc, other constituents in a coating formula, and the environment are rarely described in any detail. And it's a crucial description because it sends us two important messages:

One is that, for the most part, the coatings industry hasn't gotten all that it can out of zinc-rich coatings. That's been to the detriment of customers, their assets, and the environment.

And two, the recipe to do better is no mystery. The industry has what it needs—and has had it for decades.

The behavior of zinc in inorganic and organic systems

In zinc-rich coatings, the reaction between zinc and the atmosphere is key to the extended corrosion protection we're all familiar with.

Immediately on its exposure to the environment, zinc reacts with oxygen, moisture, and carbon dioxide in the air to form numerous reaction products. These reaction products fill in microscopic pockets in the coating film over time, a process which continually reinforces the structure of the coating and is essential to its overall protective properties.

But the coating's resin type is also instrumental to its performance. Inorganic zinc-rich coatings are typically based on silicate resins, which are made of the same chemical tool kit as rocks or sand. Silicate-resin-based coating films are relatively permeable compared to epoxy resins. That allows moisture to move through the film for continued curing of the silicate resins, as well as reacting with zinc to continually reinforce the coating.

The zinc compounds fill the pores in the silicate resin matrix, creating a physical barrier between the substrate and its environment. The zinc also reacts with the silicate resin and the iron in steel to form a chemically bound complex. When moisture is present, the circuit is completed and cathodic protection is activated. This corrosion-resisting barrier lasts a long time because inorganic resins do not degrade under UV exposure.

So unlike their organic counterparts, which weaken over time, inorganic zinc-rich coatings strengthen as they age.

However, a problem emerges. A widely used corrosion protection system involves an inorganic zinc-rich primer under one or two organic epoxy or urethane coats. But organic-resin-based coatings are less permeable, and applying them over an inorganic zinc-rich primer insulates a portion of the zinc. That impedes its interaction with the atmosphere, and fewer zinc compounds are formed as a result.

Compounding the problem is that all organic resins eventually break down under exposure to UV radiation. The corrosion-protective performance of an inorganic zinc-rich primer is handicapped by the introduction of an organic resin on top of it.

The image below, captured by Carboline at NASA's beachside corrosion test site at Kennedy Space Center in Florida, illustrates the point. The panels marked 312 and 320 are coated in an inorganic zinc-rich primer. The two panels to their right are coated in organic-resin-based materials. Both sets of panels were set out for testing at the same time.

Inorganic zinc-rich coatings vs. galvanizing vs. metalizing

No discussion of galvanic corrosion protection should exclude the other common ways to achieve it.

Galvanizing, in one form or another, has been around for centuries. It's well understood and well regarded as arguably the premier method for achieving long-lived corrosion protection.

Metalizing, a more recent invention, has gained traction for its apparent very strong performance, too.

How do liquid-applied coatings compare? It's hard to offer a definitive and scientifically valid performance comparison for two reasons:

- Neither galvanizing nor metalizing are subject to the same rigorous performance testing as paint; paint is held to a different and higher standard

- Variability in assets, surface preparation, application techniques, formulas, environmental exposures, and other influences mean control conditions are difficult to achieve

With that said, our stance is that a premium inorganic zinc-rich primer, when applied in one coat to a properly prepared surface, is equal or superior in performance to galvanizing. Galvanizing is usually marketed as a 50-year corrosion protection solution.

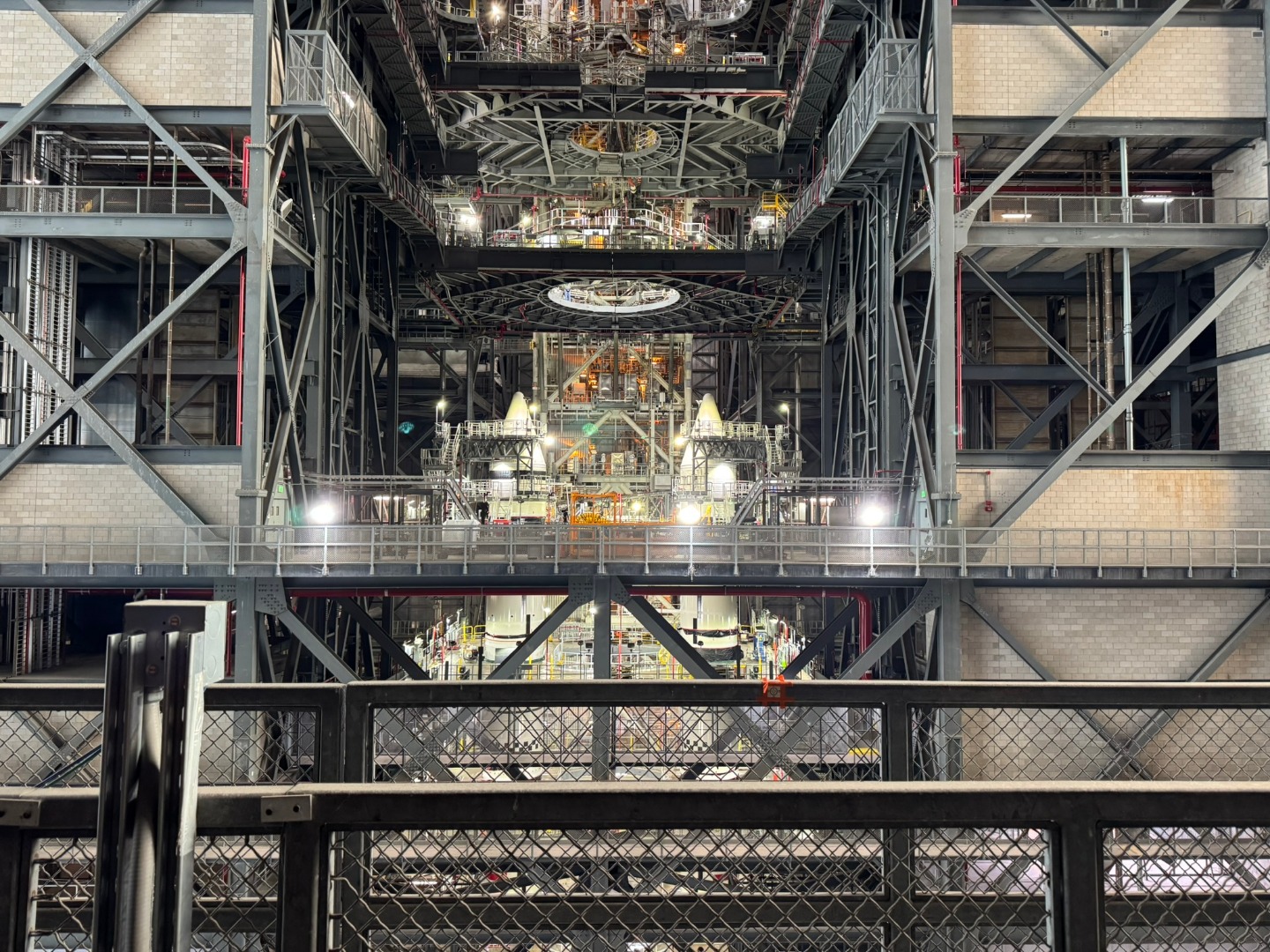

It's worth noting that the structural steel in NASA's Vehicle Assembly Building in coastal Florida was coated in a single layer of Carbozinc 11 in 1966. It was observed in excellent condition as recently as February 2025, 59 years later.

Metalizing is a new enough process that we'd need to see a 50-year performance history before agreeing that it was on par with inorganic zinc-rich coatings or galvanizing. Time will tell.

Cost, application properties, and health and safety matters are easier to compare:

- Galvanizing is slower, and metalizing much slower, than applying paint; paint application equipment is far more portable

- Galvanizing and metalizing involve exposure to high heat and dangerous chemicals; the health exposures associated with using zinc-rich coatings and application equipment are quite mild by comparison

- Galvanizing is markedly more costly than painting—sometimes twice the cost per square foot for large steel members—while metalizing is monstrously expensive at three to four times the cost to paint

Listen to this episode of The Red Bucket podcast for a more detailed discussion on performance comparisons of galvanizing, metalizing, and inorganic zinc-rich coatings.

Could two-coat inorganic systems maximize corrosion protection potential?

If inorganic zinc-rich coatings are such phenomenal performers when left alone, then why would we introduce the question of a two-coat system?

From a performance perspective, testing has shown that the additional inorganic coating layer may increase the system's durability and resistance to impact damage while still offering excellent galvanic protection. Test panels coated in Carboline's Armorlast two-coat inorganic system have shown virtually no degradation following exposure in back-to-back-to-back ISO 12944-9 cyclic aging tests. A single test cycle simulates 25 years in the harshest, most corrosive conditions.

Indeed, compelling test data along with extensive past experience with inorganic systems led NASA to choose the Armorlast system for the structural steel of its new ML-2 launcher.

The Armorlast two-coat inorganic coating system protects the structural steel of NASA's ML-2 launcher. Designed to support NASA's Artemis program, the launcher is currently under construction at Kennedy Space Center in Florida. Image courtesy of Bechtel.

Beyond performance, another benefit that emerges is color options.

That's because with single-coat inorganic zinc-rich coatings, all you get is zinc dust gray. But an added inorganic finish coat means more colors are available, and the days of giving up on performance for visual appeal, or vice versa, are finally over.

Owners of highly visible assets in harsh environments—offshore energy platforms or wind turbines, bridges, commodity storage terminals, and more—are already taking notice.

The performance benefits and cost savings speak for themselves, and they're too loud to ignore.