CTSP Episode 160 - Is a coating dry? Or is it cured?

Jack Walker and Paul Atzemis discuss the definitions of the varying stages during the curing process of a high-performance coating.

Jack Walker and Paul Atzemis discuss the definitions of the varying stages during the curing process of a high-performance coating.

Dustin Young of SSPC joins Jack Walker and Paul Atzemis to discuss new concrete standards from SSPC. The trio discusses the new concrete abrasive blasting standards SSPC CAB 1-3.

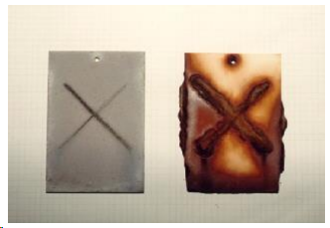

Design considerations for steel bridge coatings include exposure environment, aesthetics, application, and cost. Steel bridge coatings must offer protection against corrosion. Current techniques include traditional three-coat zinc, epoxy, urethane systems, galvanizing, and thermal spray metallization. Another pathway for steel protection includes the use of decades-old inorganic zinc spray-applied coatings. This approach offers the performance of a metallized coating while using conventional spray application. What's new is the use of an inorganic topcoat that maintains performance and shop throughput while adding color and aesthetics. This study will compare a two-coat inorganic coating system alongside galvanized, thermal spray metallizing, and sealed thermal spray metallizing systems in corrosion resistance lab testing. A discussion of applied cost and throughput will be presented, along with a review of the chemistry of this approach and the sustainability benefits it offers.

With the release of preliminary National Transportation Safety Board (NTSB) findings suggesting a likely cause of the collapse of the Fern Hollow Bridge in Pittsburgh, Pennsylvania, we ask: Should uncoated corten or weathering steel be coated anyway? Read why the answer is complicated.

Jack Walker and Paul Atzemis hit the concrete. In this episode, they discuss the details of SSPC-SP13/NACE No. 6 The Surface Prep of Concrete. They discuss the importance of moisture tests and the