CTSP Episode 189 - AMPP update with Bob Chalker part 2

A continuation of the discussion about AMPP with CEO Bob Chalker. Make sure to listen to part 1 (Episode 188) before you listen to this episode.

A continuation of the discussion about AMPP with CEO Bob Chalker. Make sure to listen to part 1 (Episode 188) before you listen to this episode.

Jack Walker and Paul Atzemis are again at SSPC Coatings+. This time, they are joined by Nicole Lourette (Event Specialist) and Michael Kline (Director of Technology and Communications). The group

Jack Walker and Paul Atzemis continue their exploration into the cost of different coating technology. This week the duo focuses on topcoats as they explore polyurethanes, siloxanes, polyureas, and...

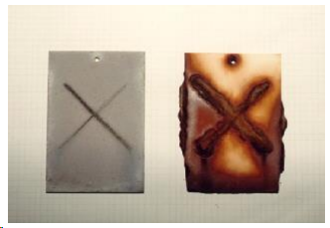

Design considerations for steel bridge coatings include exposure environment, aesthetics, application, and cost. Steel bridge coatings must offer protection against corrosion. Current techniques include traditional three-coat zinc, epoxy, urethane systems, galvanizing, and thermal spray metallization. Another pathway for steel protection includes the use of decades-old inorganic zinc spray-applied coatings. This approach offers the performance of a metallized coating while using conventional spray application. What's new is the use of an inorganic topcoat that maintains performance and shop throughput while adding color and aesthetics. This study will compare a two-coat inorganic coating system alongside galvanized, thermal spray metallizing, and sealed thermal spray metallizing systems in corrosion resistance lab testing. A discussion of applied cost and throughput will be presented, along with a review of the chemistry of this approach and the sustainability benefits it offers.

Jack Walker and Paul Atzemis discuss the AWWA C222 standard. This standard relates to the use of polyurethanes and polyurea for the interior and exterior of steel water pipe, valves, and fittings.