CTSP Episode 075 - Life Expectancy of Coatings, Corrosion 2019

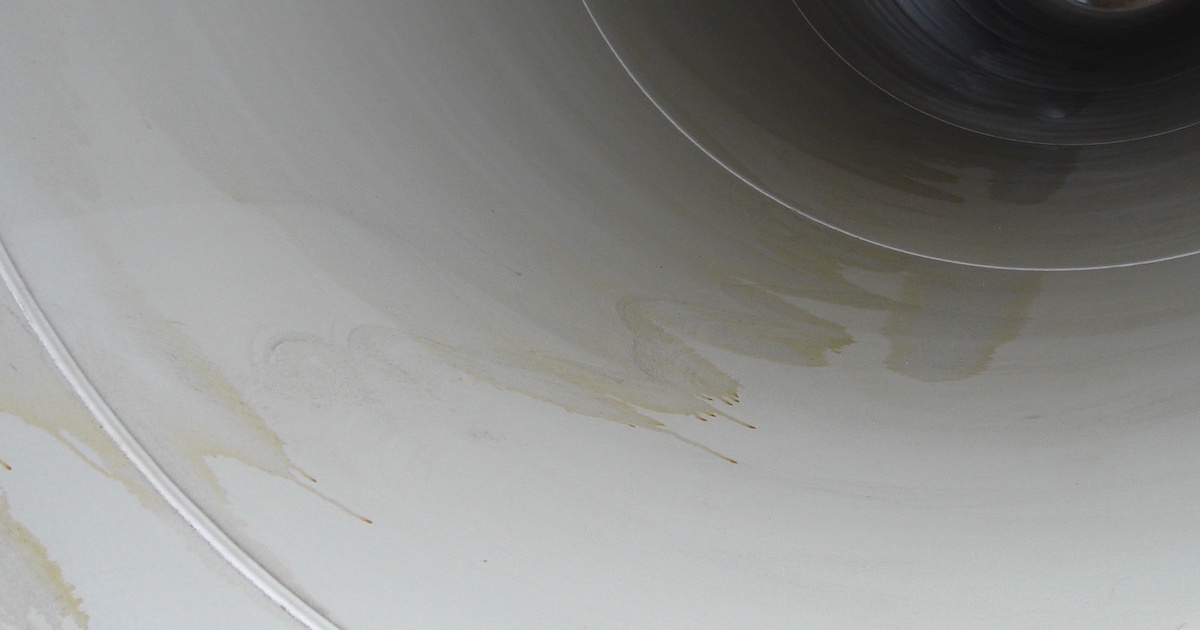

Jack Walker and Paul Atzemis discuss how long a coating system should last. They discuss the conditions that effect the service life of coatings and how to improve that life cycle.

Jack Walker and Paul Atzemis discuss how long a coating system should last. They discuss the conditions that effect the service life of coatings and how to improve that life cycle.

Intumescent fireproofing materials are often specified when aesthetics matter. Learn more about intumescents as we conclude our passive fire protection series.

New to the world of fireproofing? Learn all the basics of passive fire protection—from what it is and why it’s important to best practices and fire test standards.

Jack Walker and Paul Atzemis continue the discussion of Corrosion Under Insulation (CUI) with an in-depth explanation of the NACE SP0198 categories and the appropriate coatings for each. Make sure to

Amine blushing is a common coating failure that can wreak havoc on your coated surface. These best practices will help you identify, prevent and remediate this pesky issue.