Archive

Inorganic zinc-rich coatings: How they work, and how they can work better

Old technology sets a new standard in corrosion protection thanks to a better understanding of the behavior and properties of zinc within inorganic coating systems.

Red Bull's transformation in Madrid

Red Bull Spain now occupies new headquarters in Madrid following the extensive renovation of a building previously used as an engineering college. Architecture firm yyplusplus designed furnishings and partitions to transform the open, noisy atmosphere into a pleasant space suitable for office work. They selected Farbocustic gypsum-based interior insulation because it combines excellent acoustic properties, a visually appealing finish, and safe natural fibers that enhance applicator and occupant safety.

The Red Bucket – Episode 24. Fluoropolymers: The unbeatable resin technology for water tank topcoats (Feat. Jeremy Sukola and Kristen Blankenship)

Fluoropolymer-based finish coats are the premier performers for elevated water storage tanks in exterior exposures. The specialty FEVE resin on which they are based withstands intense UV radiation, high winds, and intense precipitation while holding gloss and color for decades. And while all that comes at a cost, water industry expert Jeremy Sukola and chemistry nerd Kristen Blankenship explain how that cost represents a long-term investment that boasts a handsome return. In this episode of The Red Bucket, learn the chemistry, use cases, and regulatory considerations of fluoropolymer topcoats. Also, Kristen ponders the Atlantic Ocean from the top of a cliff, and Jeremy shares a strong opinion about spaghetti sauce.

The Red Bucket – Episode 23. Acrylamide leak sealing grouts (Feat. Michael Vargo)

Acrylamide grout technology dominates the underground wastewater collection leak-sealing landscape. Legacy dry-granule and modern liquid variants give operators tremendous flexibility to address challenges of almost any scope or scale. But how do acrylamides work? Why do they work so well? And what do municipalities or private network owners need to know about how they fit into the broader maintenance and repair ecosystem? Michael Vargo of Prime Resins is the man with the answers. Also, Michael considers what it would be like to be 6'10”.

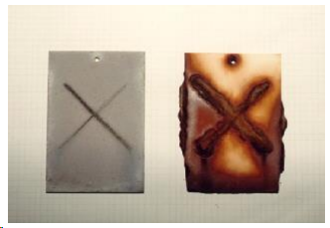

Two-coat inorganic coating system for steel bridges

Design considerations for steel bridge coatings include exposure environment, aesthetics, application, and cost. Steel bridge coatings must offer protection against corrosion. Current techniques include traditional three-coat zinc, epoxy, urethane systems, galvanizing, and thermal spray metallization. Another pathway for steel protection includes the use of decades-old inorganic zinc spray-applied coatings. This approach offers the performance of a metallized coating while using conventional spray application. What's new is the use of an inorganic topcoat that maintains performance and shop throughput while adding color and aesthetics. This study will compare a two-coat inorganic coating system alongside galvanized, thermal spray metallizing, and sealed thermal spray metallizing systems in corrosion resistance lab testing. A discussion of applied cost and throughput will be presented, along with a review of the chemistry of this approach and the sustainability benefits it offers.